Purpose-Built Shelters for Aggregate Quality and Consistency

Varna Shelters has honed its storage solutions over the years to address the unique needs of critical US industries. In the aggregates and bulk materials sector, where exposure to weather can quickly compromise material quality, reliable, weatherproof storage is essential. Our shelters are engineered to safeguard valuable materials in even the most variable climates, ensuring durability, compliance, and operational efficiency.

Exposure to weather can degrade bulk materials like ballast or Type 1, leading to reduced quality and increased costs. Varna Shelters’ SkyShield™ container canopies provide a modular solution tailored for US aggregate yards. For example, we equipped a client with a customized SkyShield™ system to shield their ballast stockpile, preventing rain from compromising material integrity or causing separation. By protecting materials from environmental damage and contamination, SkyShield™ enables operators to minimize waste, ensure compliance, and maintain profitability year-round.

Unprotected stockpiles in the US often require annual reprocessing or cycling—removing, drying, and restocking aggregate to maintain quality. Rain-induced water retention can increase aggregate weight by 5–8%, leading to transport inefficiencies as you pay to move water instead of usable material. This disrupts batching accuracy and escalates haulage and material expenses. Rehandling typically adds 10–15% more labor and equipment time, straining workforce hours and accelerating wear on machinery. The combined time, energy, and fuel costs—particularly for re-drying—can amount to thousands per week on high-volume sites.

Exposure to weather can degrade bulk materials like ballast or Type 1, leading to reduced quality and increased costs. Varna Shelters’ SkyShield™ container canopies provide a modular solution tailored for US aggregate yards. For example, we equipped a client with a customized SkyShield™ system to shield their ballast stockpile, preventing rain from compromising material integrity or causing separation. By protecting materials from environmental damage and contamination, SkyShield™ enables operators to minimize waste, ensure compliance, and maintain profitability year-round.

Unprotected stockpiles in the US often require annual reprocessing or cycling—removing, drying, and restocking aggregate to maintain quality. Rain-induced water retention can increase aggregate weight by 5–8%, leading to transport inefficiencies as you pay to move water instead of usable material. This disrupts batching accuracy and escalates haulage and material expenses. Rehandling typically adds 10–15% more labor and equipment time, straining workforce hours and accelerating wear on machinery. The combined time, energy, and fuel costs—particularly for re-drying—can amount to thousands per week on high-volume sites.

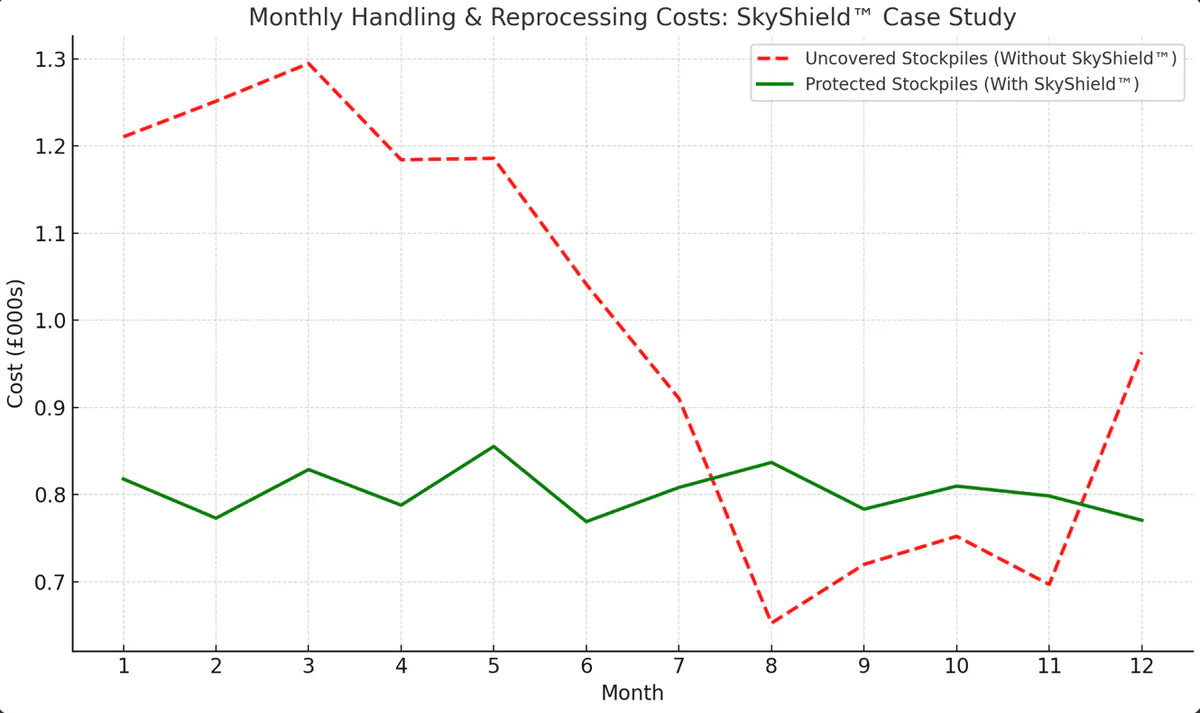

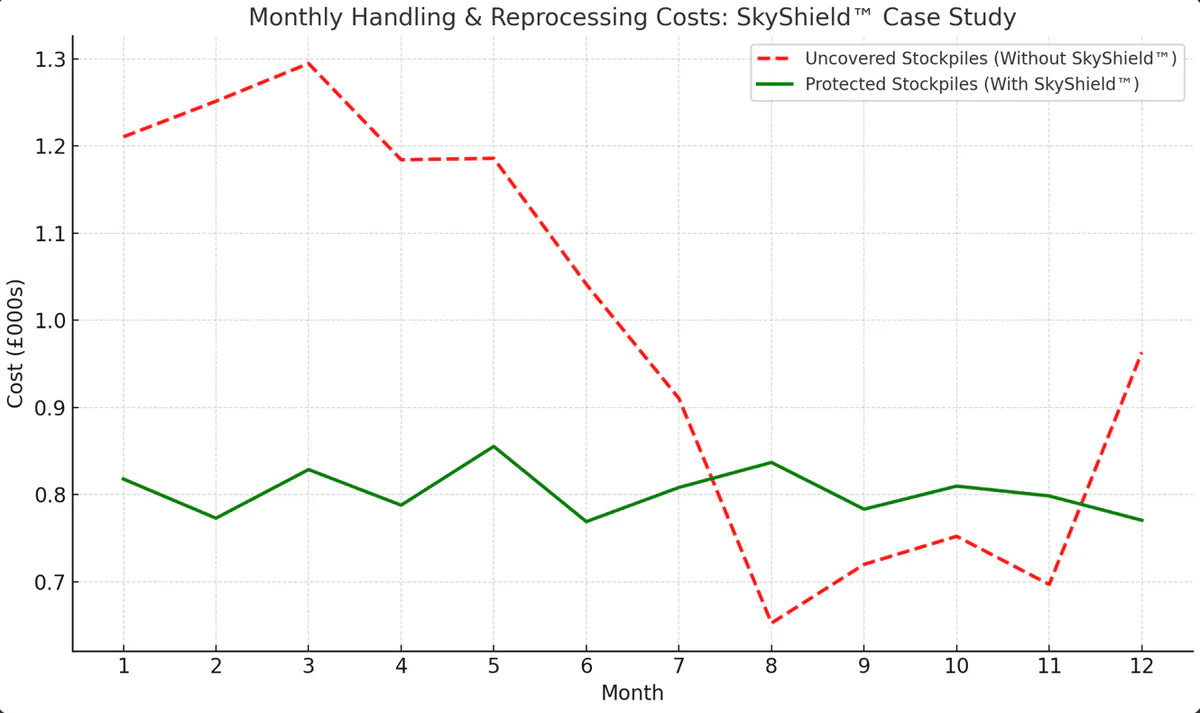

This case study evaluates the monthly reprocessing and handling expenses of a high-volume US aggregate yard with and without SkyShield™ protection. Unprotected stockpiles faced significant cost increases from rain-soaked materials, added water weight, and frequent rehandling. In contrast, the SkyShield™-protected yard maintained consistent material quality, eliminating the need for drying, reshuffling, or batch corrections. Over a year, SkyShield™ achieved an estimated 25–30% reduction in material handling costs, while also enhancing compliance and reducing equipment wear. For operators handling thousands of tons monthly, these savings can scale into tens of thousands of dollars.

This case study evaluates the monthly reprocessing and handling expenses of a high-volume US aggregate yard with and without SkyShield™ protection. Unprotected stockpiles faced significant cost increases from rain-soaked materials, added water weight, and frequent rehandling. In contrast, the SkyShield™-protected yard maintained consistent material quality, eliminating the need for drying, reshuffling, or batch corrections. Over a year, SkyShield™ achieved an estimated 25–30% reduction in material handling costs, while also enhancing compliance and reducing equipment wear. For operators handling thousands of tons monthly, these savings can scale into tens of thousands of dollars.

SkyShield™ Container Canopy – Aggregates Industry FAQ

How quickly can SkyShield™ systems be installed?

Most SkyShield™ canopies are set up within 2–5 working days from delivery, depending on site access and canopy size. We pre-assemble units off-site to minimize downtime during installation.

Do SkyShield™ canopies require planning permissions in the US?

In most cases, no. The modular, container-based design of SkyShield™ qualifies as temporary or semi-permanent infrastructure, ideal for fast-paced projects, transportation hubs, or short-term aggregate storage contracts.

Are SkyShield™ systems relocatable or expandable?

Yes, SkyShield™ canopies are fully modular, relocatable, and reusable, making them perfect for dynamic sites, short-term projects, or leased yards. Additional canopy bays can be integrated as your material volumes increase.

What types of materials can SkyShield™ canopies protect?

SkyShield™ canopies are designed to store various bulk construction materials, including Type 1, MOT, ballast, sand, recycled aggregates, and more. They shield against rain, UV exposure, and wind, preventing material degradation and cross-contamination.

How does exposure to rain affect aggregates?

Rain exposure increases moisture content in aggregates, adding transport weight, altering compaction, and disrupting mixing ratios. Excessive water can also cause fines to separate or wash away, reducing material quality.

Can SkyShield™ canopies reduce operational costs?

Yes, by keeping materials dry and uncontaminated, SkyShield™ canopies eliminate the need for annual stockpile cycling, manual reprocessing, and re-drying. Many clients achieve up to 30% savings in labor and equipment time associated with handling wet or contaminated materials.